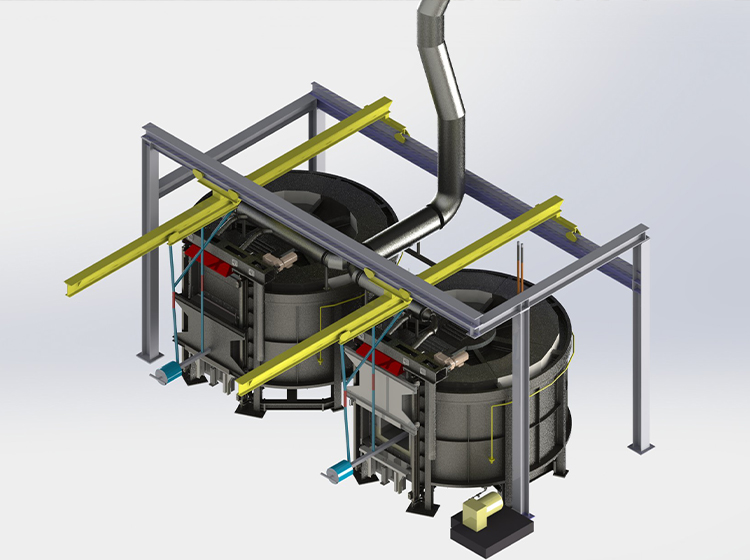

Rotary Hearth Furnaces

Plants.

SCHLAGER rotary hearth furnaces are preferably used for work pieces with high cycle rates in order to carry out the heat treatment in a liquid process. To keep heat loss to a minimum during the short cycle rates, the doors have only the minimum required aperture height and width. For this reason, moreover, the process speed of the door is selected high. These measures enable us to ensure effective atmosphere recirculation at low process temperatures.

Characteristic by a rotary hearth furnace is a round, rotating hearth. Charging by robots is possible without any problems, because our PLC provides the necessary interfaces for real-time data exchange with the robot control system.

Batch Weights:

– up to 20.000 kg/h

Operating Temperatures:

– between 500 °C to 1.300 °C

Energy Efficiency:

– Recirculation of exhaust energy by effective recuperators

– Efficient ceramic fibre insulation ensures low energy consumption

Heating by:

– High speed or flat flame burner

– Most modern recuperative and regenerative heating systems

– Economical & resource-saving

Benefits:

– Separation of the furnace atmosphere from the ambient air by our sealing systems

-> Increase of heat transfer & temperature accuracy

Refractory:

– Refractory lining by shaped bricks, ceramic fibres, ceramic fibre modules and insulation boards.

-> depending on the operation and use of the equipment

Work Pieces

Sectors

- Forgings

- Steel

- Heat treatment

- Castings and tubes

- Aluminum

- Profiles

- Slabs / Ingots

- and much more

- Forging industry

- Aerospace industry

- Steel industry

- Heat treatment industry

Not yet found the right solution for you?

Feel free to contact us! We will make you an offer according to your individual requirements.