Refractory

Services.

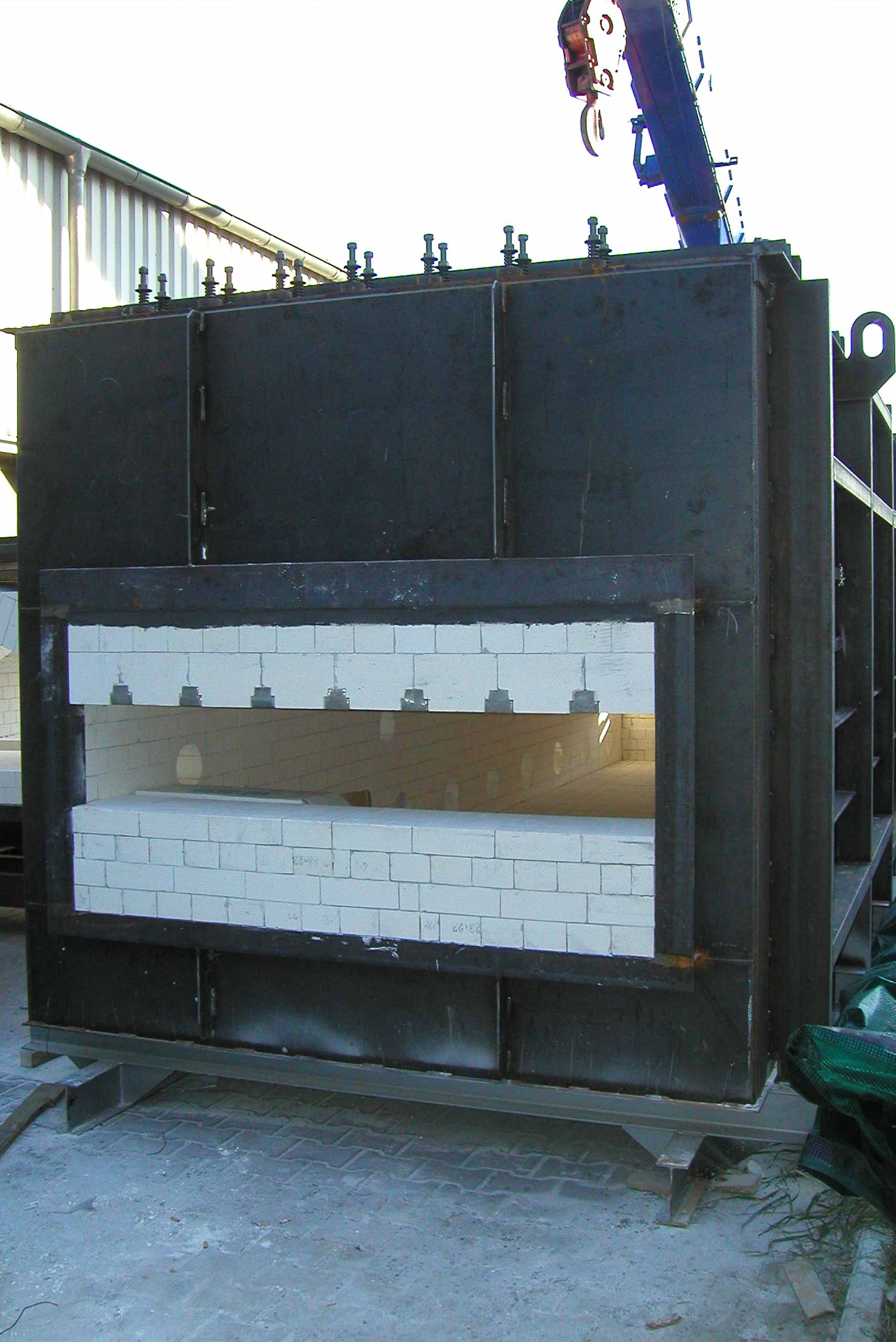

As a specialist in all aspects of industrial furnace construction, we have been offering you numerous technical thermal insulation services since 1984. Our highly qualified engineers select for you the optimal techniques and materials for the insulation of your plants. SCHLAGER GmbH continues to focus on high quality as well as efficiency and determines the most sensible and energy-saving variant for you on the basis of heat transfer calculations.

Request now

First class energy efficiency

We work to the highest quality standards and have the refractory lining requirements of your industrial furnace determined by experienced specialists in the field of heat treatment.

With the refractory materials customized for you, we strive for maximum furnace productivity and thus optimal energy utilization. Customization in each individual project allows the refractory to be exercised effectively, ensuring first-class energy efficiency as well as low heat loss.

– OUR SERVICES AT A GLANCE:

- Advice on the selection of insulation materials.

- Thermal transmittance calculations and construction.

- Measurements and checks according to heat treatment specifications, such as AMS 2750 or NORSOK M 650 and ASTM A 991.

- Complete relining (with and without inert gas atmosphere).

- Partial renovations of individual areas.

- Renewal of the door portals.

- Replacement of support frames.

- Emergency repairs.

- Refractory products from reputable manufacturers.

- Casting and gunning mixes, lightweight refractory bricks, ceramic fiber products , insulation boards, molded parts.

With the refractories customized for you, we strive for maximum furnace productivity and thus optimum energy utilization. Customization in each individual project allows the refractory to be exercised effectively, ensuring first-class energy efficiency as well as low heat loss.

Not yet found the right solution for you?

Feel free to contact us! We will make you an offer according to your individual requirements.