Modernisation

Services.

Modernising plants is a profitable way to increase energy efficiency, improve production quality and meet current legal requirements, compared to purchasing new plants,

extend the life of the plant and meet current legal requirements.

Our expert staff offers you comprehensive technical support.

We support you in all problem situations, both for all SCHLAGER systems and for existing third-party products.

Your path to energy efficiency

Save energy and emissions! Energy savings of 30-60% are economically achievable with many old systems, this means amortisation periods of 1-3 years.

- Step 1: Recording the actual status

- Step 2: Exhaust gas analysis & burner settings

- Step 3: Periodical service

- Step 4: Checking the sealing systems

- Step 5: Review of the control systems

- Step 6: Modernisation of the existing plant

"Are my existing plants working as efficiently as they can?"

Our experts record the actual condition of your system and determine the need for action based on a thermographic analysis. In a detailed report you will see your savings potential. We advise you expertly and individually adapted to your plant.

The next step to efficient and low-emission gas-fired heating is expertly adjusted burners.

The flue gas analysis shows the proportion of pollutants and residual oxygen in the flue gas. To comply with the limit values for pollutant emissions and to optimise combustion, regular flue gas analysis and adjustment of the burner settings are necessary.

Regular servicing ensures that your system runs efficiently and trouble-free over the long term.

During maintenance, burners are repaired and adjusted, repairs are carried out and system damage is detected at an early stage. Damage in need of repair can not only cause further, ever-increasing damage, but also cost energy. This makes it all the more important to detect and repair them at an early stage.

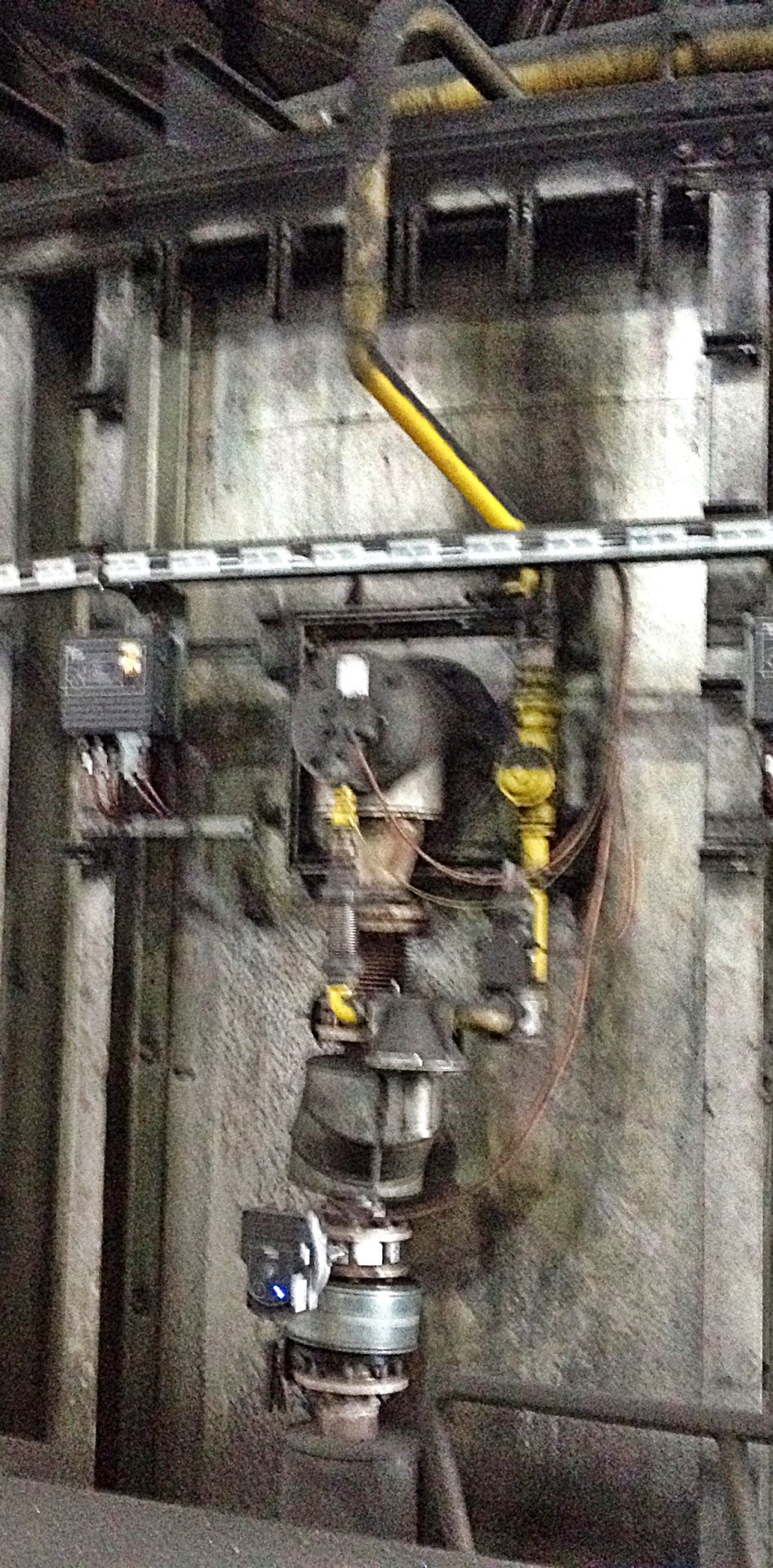

The main cause of energy losses are leaks and defective oven pressure controls.

SCHLAGER has proven techniques for sealing doors and hearth carriages that can also be used as retrofit systems on existing installations. Retrofitting with modern sealing systems is easy to implement and has an incredible ROI.

By retrofitting modern measurement and control technology, it is possible to optimise the control of burners or flue gas routing in such a way that not only energy can be saved, but also significant improvements in temperature uniformity in the oven chamber can be achieved.

As a last step, an individual modernisation of the existing system can be done.

We check and evaluate for you the use of alternative burners, the flue gas system and any recuperators that may have been installed, and advise you on whether a conversion to electric heating is feasible.

Modernising the burner technology, insulation and control technology and adapting the flue gas system is the means to optimum efficiency.

Adapted to your specific requirements.

Many old plants are real "energy guzzlers". In times of rising energy prices, immense energy savings can be achieved by modernising existing old systems. We reduce energy losses by refurbishing using the latest technologies. In this way, we guarantee you the highest energy efficiency.

– OUR SERVICES AT A GLANCE

- Energy savings through optimized burner technology, control and insulation.

- The use of state-of-the-art recuperator, regenerative and split-flow burners guarantees maximum energy efficiency and minimum pollutant emissions.

- Reduce energy losses by repairing and improving insulation.

- Adaptation of the temperature accuracy to the current heat treatment regulations.

- Measurements and checks according to heat treatment specifications, such as AMS 2750 or NORSOK M 650 and ASTM A 991.

- Sealing systems for oven doors and bogies, etc.

- Expansion and modernization of the furnace controls including process visualization.

- Adjustment of the furnace size to the current needs. (Enlargements / Reductions).

- Adaptation of existing furnace systems to current safety regulations.

- Increase in production capacity.

Not yet found the right solution for you?

Feel free to contact us! We will make you an offer according to your individual requirements.